MODULE 6 – MATERIALS AND HARDWARE – exam only

Delivery methods: classroom only

Group Size: limited up to 15 [PL]

Language: polish

Taking the Exam

Exams will be held starting at 11:00 AM in the Zephirius building (4th floor) at GTC or on the LOTAMS premises.

In the examination room, aside from your identification, a pen, and tests on the desks, nothing else can be placed.

After completing the exam, the filled-out test must be submitted to the examiner.

End of Examination

Upon completion of the exam, candidates are obligated to vacate their stations in the examination room and the training infrastructure as quickly as possible.

Information regarding the exam results will be provided either by phone or email after verifying identification details

Duration of exam:

Category B1: 72 multi-choice and 0 essay questions. Time allowed 90 minutes.

Category B2: 60 multi-choice and 0 essay questions. Time allowed 75 minutes.

Content:

6.1 Aircraft Materials — Ferrous

(a)

- Characteristics, properties and identification of common alloy steels used in aircraft;

- Heat treatment and application of alloy steels.

(b)

- Testing of ferrous materials for hardness, tensile strength, fatigue strength and impact resistance.

6.2 Aircraft Materials — Non-Ferrous

(a)

- Characteristics, properties and identification of common non-ferrous materials used in aircraft;

- Heat treatment and application of non-ferrous materials;

(b)

- Testing of non-ferrous material for hardness, tensile strength, fatigue strength and impact resistance.

6.3 Aircraft Materials — Composite and Non-Metallic

6.3.1 Composite and non-metallic other than wood and fabric

(a)

- Characteristics, properties and identification of common composite and non-metallic materials, other than wood, used in aircraft;

- Sealant and bonding agents;

(b)

- The detection of defects/deterioration in composite and non-metallic material;

- Repair of composite and non-metallic material.

6.3.2 Wooden structures

- Construction methods of wooden airframe structures;

- Characteristics, properties and types of wood and glue used in aeroplanes;

- Preservation and maintenance of wooden structure;

- Types of defects in wood material and wooden structures;

- The detection of defects in wooden structure;

- Repair of wooden structure.

6.3.3 Fabric covering

- Characteristics, properties and types of fabrics used in aeroplanes;

- Inspections methods for fabric;

- Types of defects in fabric;

- Repair of fabric covering.

6.4 Corrosion

(a)

- Chemical fundamentals;

- Formation by, galvanic action process, microbiological, stress;

(b)

- Types of corrosion and their identification;

- Causes of corrosion;

- Material types, susceptibility to corrosion.

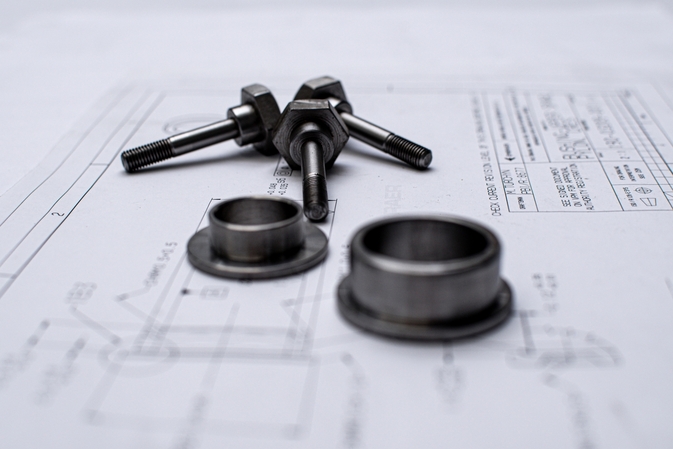

6.5 Fasteners

6.5.1 Screw threads

- Screw nomenclature;

- Thread forms, dimensions and tolerances for standard threads used in aircraft;

- Measuring screw threads.

6.5.2 Bolts, studs and screws

- Bolt types: specification, identification and marking of aircraft bolts, international standards;

- Nuts: self locking, anchor, standard types;

- Machine screws: aircraft specifications;

- Studs: types and uses, insertion and removal;

- Self tapping screws, dowels.

6.5.3 Locking devices

- Tab and spring washers, locking plates, split pins, pal-nuts, wire locking, quick release fasteners, keys, circlips, cotter pins.

6.5.4 Aircraft rivets

- Types of solid and blind rivets: specifications and identification, heat treatment.

6.6 Pipes and Unions

(a)

- Identification of, and types of rigid and flexible pipes and their connectors used in aircraft;

(b)

- Standard unions for aircraft hydraulic, fuel, oil, pneumatic and air system pipes.

6.7 Springs

- Types of springs, materials, characteristics and applications.

6.8 Bearings

- Purpose of bearings, loads, material, construction;

- Types of bearings and their application.

6.9 Transmissions

- Gear types and their application;

- Gear ratios, reduction and multiplication gear systems, driven and driving gears, idler gears, mesh patterns;

- Belts and pulleys, chains and sprockets.

6.10 Control Cables

- Types of cables;

- End fittings, turnbuckles and compensation devices;

- Pulleys and cable system components;

- Bowden cables;

- Aircraft flexible control systems.

6.11 Electrical Cables and Connectors

- Cable types, construction and characteristics;

- High tension and co-axial cables;

- Crimping;

- Connector types, pins, plugs, sockets, insulators, current and voltage rating, coupling, identification codes.

Who should attend: Technical personnel in aircraft maintenance or engineering.

Standard: EASA Part 66 (APPENDIX TO ANNEX III) / EASA Part 147

Prerequisites:

A background in commercial aviation together with a general awareness of the regulatory

is an advantage.

Exam completion Standard:

Exam pass mark: minimum 75%.

Exam type: multiple-choice questions.

Certification:

Certificate of recognition

Additional information

| Date picker | 2026.01.22 B1, 2026.02.24 B2, 2026.03.05 B1, 2026.03.26 B2 |

|---|